84 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

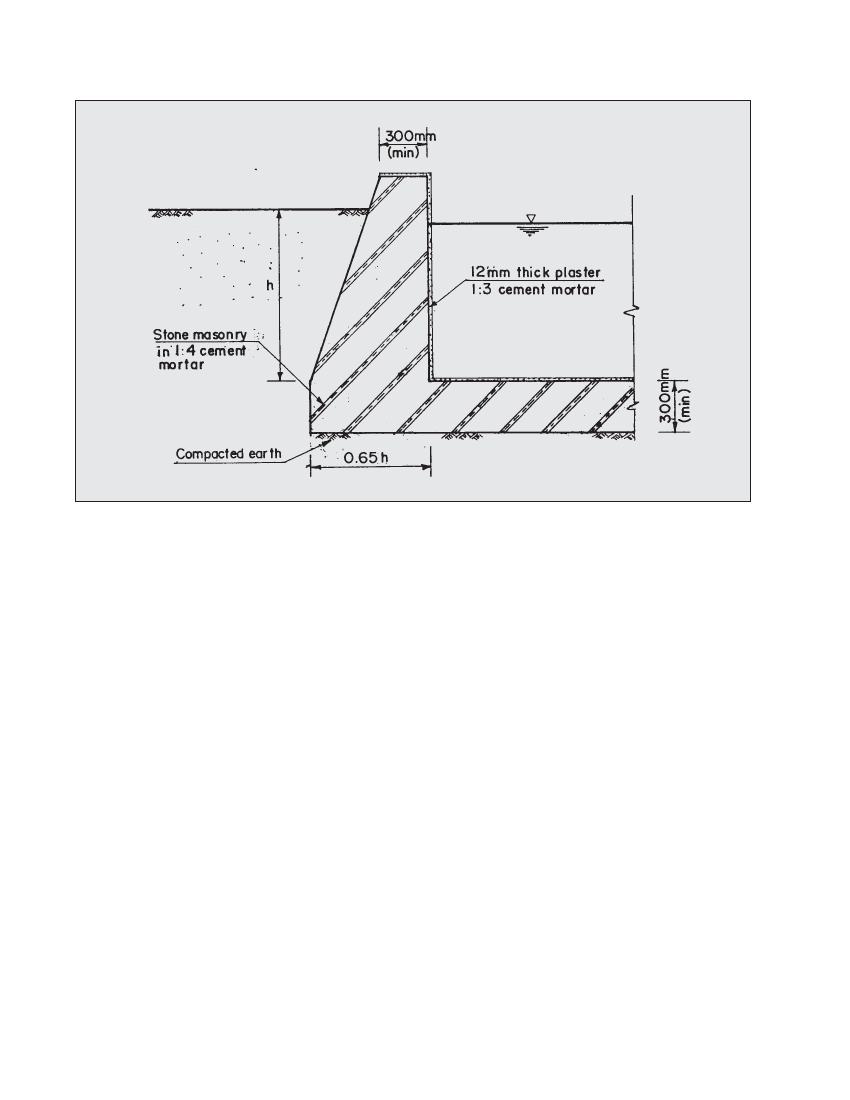

Figure 5.9 Wills and floors of water retaining

If the vertical face is towards the soil, the water volume in

the basin will increase but structural stability will be

slightly reduced.

The internal surface (water retaining surface) of the walls

and the surface of the floor should be plastered using 1:3

cement sand mortar to a thickness of 12 mm. This

significantly minimises the likelihood of seepage.

Finally, the walls and the floor should be cured as discussed

in Chapter 4. Another option is to use reinforced concrete

for the floor and walls. However this is more expensive

and also requires skilled labour, so is not generally

recommended for micro-hydro schemes.

5.6 Checklist for gravel trap,

settling basin and forebay work

Can the gravel trap, settling basin and the forebay or at

least two of these structures be combined together?

Are these structures located such that excess water can be

spilled safely, without causing erosion or stability problems?

Is the settling basin sized such that the emptying frequency is

once to twice daily during high flows? Also, does dlimitcorrespond

to the head and turbine type? Refer to Section 5.3.3.

Is secondary settling required at the forebay? Is the forebay

large enough for manual cleaning and is a spillway

incorporated in this structure? Has the submergence head

been checked?

Once these structures have been sized, refer to Section 5.5

for the construction details