CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

135

10. Innovations

10.1 General

A number of innovative ideas, research, applications and pilot

projects relevant to micro-hydro technology that have not yet

been fully field tested, especially in the Nepalese context, are

discussed in this chapter. Some applications are in the research

and development stage, others have been successfully

implemented in other countries or carried out as “pilot

projects” in Nepal.

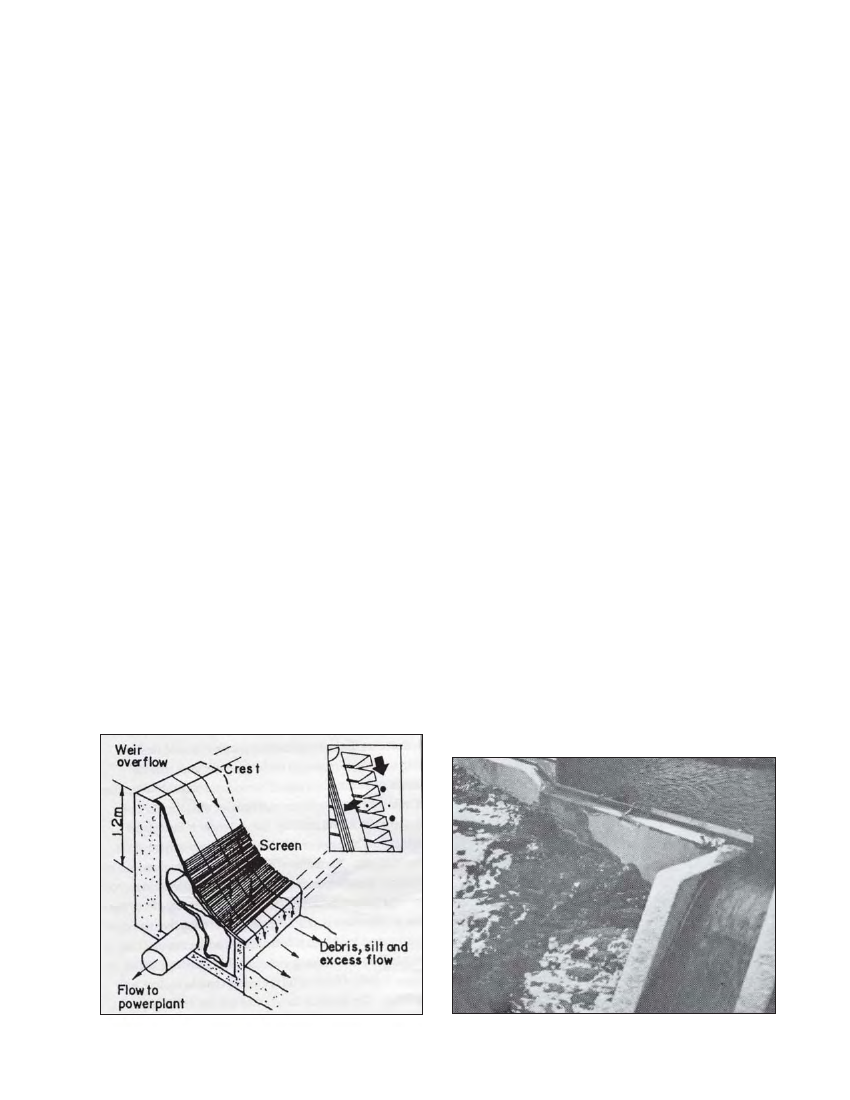

10.2 Coanda intake

A Coanda intake has a special screen that utilises the tendency

of fluids to follow a surface. This is known as the “Coanda

effect”. As shown in Figure 10.1, the Coanda screen is installed

along the crest of the diversion weir and is shaped in the

ogee curve configuration. A curve acceleration plate at the

top of the screen stabilises and accelerates the flow. As the

flow passes over the screen surface, the shearing action of the

bars combined with the Coanda effect separates the flow.

Clean water passes down through the screen whereas

sediment and debris pass over the screen to rejoin the water

course below the weir.

On rivers carrying cobbles and boulders during flood, the

Coanda intake must be carefully located so that heavy bedload

does not pass over the screen and damage it.

The potential advantages of the Coanda intake are on

particular sites which suffer from exposure to high silt load or

which offer scope for cost savings in the headrace. In the first

case, the intake can reduce the need for large or multiple

settling basins. In the second case, where a site layout is

suitable, it may be possible to commence the penstock run

directly from the Coanda, gaining head and avoiding the

need for a headrace canal. Of course, this might imply that

the penstock is longer than other potential layouts or that it

runs close to the river. A thorough financial and technical

analysis of the options is required before making a decision

on the suitability of the Coanda for a particular site.

The Coanda screens are fabricated to a high tolerance from

stainless steel. The supplier of the Coanda screens (also called

“Aqua Shear Screens”) in Europe, Dulas Limited, Wales UK,

claims that screens can be produced with 0.5 mm to even 0.2

mm clear spacings, which eliminate 90% of 0.25 mm and 0.1

mm particles respectively. Both types of screen eliminate all 1

mm particles. In most micro-hydro systems this would also

eliminate the need for a settling basin.

The flow capacity of these screens is 1401/s per metre of weir

length. A screen with a flow capacity of 401/s (0.3 m width)

costs about US$ 1380 (1997 price).

A Coanda intake has been tested at a micro-hydro site in

Wales by Dulas Ltd., in conjunction with Practical Action, UK.

Figure 10.1 A Coanda intake screen

Photo 10.1 Coanda intake of a micro-hydro scheme in Wales, UK