Power Generation-diesel Power

|

| ||||||||||||||||||||||||||||||||||||||||||||

|

Part 1: Diesel Power station → Basics

Introduction: Diesel Power station A Diesel power station(also known as Stand-by power station) uses a diesel engine as prime mover for the generation of electrical energy. This power station is generally compact and thus can be located where it is actually required. This kind of power station can be used to produce limited amounts of electrical energy. In most countries these power stations are used as emergency supply stations. Operation The diesel burns inside the engine and the combustion process moves a fluid that turns the engine shaft and drives the alternator. The alternator in turn, converts mechanical energy into electrical energy. This type of electricity generating power station will probably be used a long time into the future, due to a need for reliable stand-by electrical source for emergency situations. However, diesel power plants emit green house gases that pollute the environment and also require frequent servicing. help | edit

|

|

Part 3: Advantages v/s Disadvantages

help | edit

|

|

Part 5: Example

Power Generation-diesel Power/Part5 help | edit

|

|

Part 7: Refferences & Exercise 4

Refferences:

Execise 4:

|

|

Part 4: Calculation & Efficiency

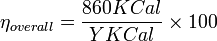

If heat produced by _X kg of oil = Y KCal (where 1kWh = 860 KCal) Then we can derive the overal power plant efficiency as:

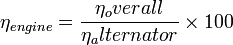

Then the engine efficiency becomes:

help | edit

|

|

Part 6: Example continued

Power Generation-diesel Power/Part6 help | edit

|

|

Part 8: Completion list

Once you finish your Exercises you can post your score here!

To post your score just e-mail your course co-ordinator your name and score Click Here

|

| |

|

|

|

|

| | Resource type: this resource contains a lecture or lecture notes. |

(in %) ... Equation 4.1

(in %) ... Equation 4.1 (in %) ... Equation 4.2

(in %) ... Equation 4.2 is specified by manufacturer

is specified by manufacturer