Power Generation-Steam Power

|

| ||||||||||||||||||||||||||||||||||||||||||||

|

Part 1: Steam Power station → Basics

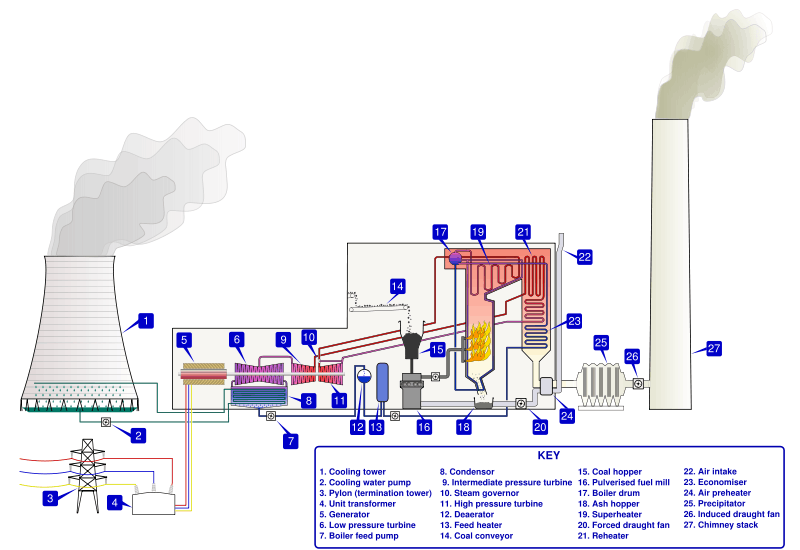

Introduction: Steam/Thermal Power station A steam/thermal power station uses heat energy generated from burning coal to produce electrical energy. This type of power station is widely used around the world. This power station uses the Rankine cycle. This is the cycle of the steam produced in the boiler, then taken to the Steam turbine (prime mover). From the turbine the steam is cooled back to water in the Condenser, the resulting water is fed back into the boiler to repeat the cycle. Because of the abundance of fuel (coal), this kind of power station can be used to produce large amounts of electrical energy. In most countries these power stations are used as base load power stations. This is because steam power stations are slow to start and can not be used to cater for peak loads that generally occur for a short duration. These power stations (together with nuclear power stations) are kept running very close to full efficiency for 24 hours a day (unless they are being maintained). They have typical life of 30 to 40 years (although most governments have reduced this number to 35 years). Pros & Cons: what this power station presents

Future generations will have to learn to depend less and less on this type of electricity generating power station, due to a fast increasing depletion of fuels (coal and oil). As other types of power stations become more efficient it should be possible to completely abandon the use of this type of power station. help | edit

|

|

Part 2: Steam Power station → Schematic arrangement

60.254.116.34 07:24, 6 July 2012 (UTC)k

help | edit

| ||||||||||||||||||||||||||||||||||||||||||

|

Part 3: Wet cooling

This is the conventional cooling method used in most steam power stations. Steam of very high purity is cooled inside the condenser and is returned to the boiler(Rankine cycle). The condenser itself uses cold water and employs the principle of heat exchange. As the cool water is returned to the boiler, the hot water in the condensor is pumped to the cooling tower. Here water is sprayed and thus falls down to the water pond under the cooling tower. As the water falls it is cooled by the natural cold air. The cooled water is pumped back to the condenser, and the cycle is repeated. This method uses a lot of water through evaporation.

help | edit

|

|

Part 4A: Indirect Dry Cooling A

The first Indirect Dry cooling method is called Wet cooled condenser. Here the condenser is still used to cool steam that is pumped back to the boiler. The hot water from the condensor is then pumped to Heat exchangers in the cooling tower and natural ventilation is used to cool the water which can then be pumped back to the condenser. Notice that water consumption here is double that consumed in the direct dry cooling method.

help | edit

|

|

Part 5: Location

The following is a list of factors that influence the selection of site for constructing a Steam power station: 1. Supply of fuel:

2. Availability of water:

3. Transportation facilities:

4. Cost & type of land:

5. Distance from populated areas:

6. Nearness to load centers:

help | edit

|

|

Part 7: Example

Sir, From steam table we can calculate the Total heat of Superheated steam at corresponding Steam inlet pressure of Turbine and Outlet of turbine. As per example --(1) steam inlet pressure of turbine is 32 kg/cm2, 450 deg. centigrade. steam outlet pressure of turbine is 10 kg/cm2 saturated. (2)steam inlet pressure of turbine is 60 kg/cm2, 450 deg. centigrade. steam outlet pressure of turbine is 10 kg/cm2 saturated. So now if we calculate heat from Steam Table, difference of Heat of (2) is coming Less than (1). Why this happen ? Power generated is less in (2) even though pressure is high. Than why we should go high pressure. Thanks, M B Kshatriya. Mobile - 76000 51274. help | edit

|

|

Part 9: Refferences & Exercise 2

Refferences:

Execise 2:

|

|

Part 4: Dry cooling

This is the more preffered Cooling method which is now being implemented in most new Steam power stations. Steam is circulated inside a radiator-like heat exchanger and is cooled by the natural cold air blown (naturally or using draught fans) between pipes of the heat exchanger. The cooled/condensed steam is returned to the boiler(Rankine cycyle). This method greatly decreases water wastages through evaporation by almost 84% of the wet cooling method. It is called Direct dry cooling since the condenser has been eliminated completely. This method is favored where water is scarce.

help | edit

|

|

Part 4B: Indirect Dry Cooling B

The second Indirect Dry cooling method is called Jet cooled condenser. Here the exhaust steam leaving the low-pressure turbine condensed by a jet spray of cold water. the resulting hot water collected is through heat exchangers in the cooling tower. The cooled water is sent back to the boiler. Notice that water consumption is equal to the previous cooling method.

help | edit

|

|

Part 6: Efficiency

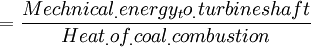

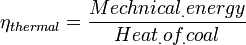

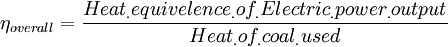

This type of power station has very high energy losses due to great heat loss in the boiler and condensor. the following equation is used to calculate power station efficiency: Thermal efficiency the above can be re-written as follows: The above generally works out to ±30% for steam power stations. you can further calculate overall efficiency as follows:

the above can be re-written as follows: The above generally works out to ±29% ( 1% loss at the generator ) for steam power stations. help | edit

|

|

Part 8: Example continued

help | edit

|

|

Part 10: Completion list

Once you finish your Exercises you can post your score here!

To post your score just e-mail your course co-ordinator your name and score Click Here

|

| |

|

|

|

|

| |

Resource type: this resource contains a lecture or lecture notes. |