Nonlinear finite elements/Homework 11

< Nonlinear finite elementsProblem 1: Small Strain Elastic-Plastic Behavior

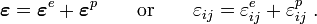

For small strains, the strain tensor is given by

In classical (small strain) rate-independent plasticity we start off with an additive decomposition of the strain tensor

Assuming linear elasticity, we have the following elastic stress-strain law

Let us assume that the  theory applies during plastic deformation of

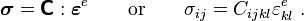

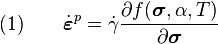

the material. Hence, the material obeys an associated flow rule

theory applies during plastic deformation of

the material. Hence, the material obeys an associated flow rule

where  is the plastic flow rate,

is the plastic flow rate,  is the yield function,

is the yield function,

is the temperature, and

is the temperature, and  is an internal variable.

is an internal variable.

Answer the following questions. Show your derivations in a clear and step-by-step manner.

Part 1

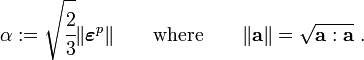

Let  be the equivalent plastic strain, defined as

be the equivalent plastic strain, defined as

Express the time derivative of  in terms of

in terms of  and

and

. This is the evolution law for

. This is the evolution law for  .

.

Part 2

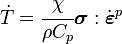

For an adiabatic process, the rate of change of temperature can be written as

where  is the Taylor-Quinney coefficient,

is the Taylor-Quinney coefficient,  is the density,

and

is the density,

and  is the specific heat. Express

is the specific heat. Express  in terms of

in terms of

and

and  . This is the

evolution law for

. This is the

evolution law for  .

.

Part 3

Write down the rate form of the elastic stress-strain law. Assume that deformations are small so that objectivity of the rates is not a concern.

Part 4

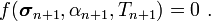

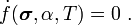

The consistency condition during plastic flow requires that

Write down an expression for the time derivative of

using the chain rule.

using the chain rule.

Part 5

Use the consistency condition and the expressions you have derived

in the previous parts to derive an expression for  in

terms of

in

terms of  ,

,  ,

,

,

,  , and

, and  .

.

Part 6

The continuum elastic-plastic tangent modulus is defined by the following relation

Derive an expression for the elastic plastic tangent modulus using the results you have derived in the previous parts.

Part 7

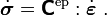

The  theory of plasticity also states that the material

satisfies the von Mises yield condition

theory of plasticity also states that the material

satisfies the von Mises yield condition

where  is the deviatoric part of the stress

is the deviatoric part of the stress  .

Derive an expression for

.

Derive an expression for  in terms of the

normal to the yield surface

in terms of the

normal to the yield surface

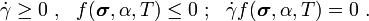

Part 8

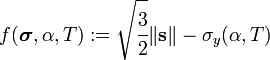

The yield stress  is given by the Johnson-Cook model

is given by the Johnson-Cook model

where  is the initial yield stress,

is the initial yield stress,  are constants,

are constants,

is a reference temperature, and

is a reference temperature, and  is the melt temperature.

Derive expressions for

is the melt temperature.

Derive expressions for  , and

, and

for the von Mises yield condition with the

Johnson-Cook flow stress model.

for the von Mises yield condition with the

Johnson-Cook flow stress model.

Part 9

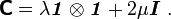

Assume that the elastic response of the material is linear, i.e.,

Derive the expression for the elastic-plastic tangent modulus for a von Mises yield condition with Johnson-Cook flow stress for a linear elastic material using the expressions that you have derived in the previous parts.

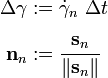

Part 10

Discretize the equations for  (equation 1),

(equation 1),

(from part 1), and

(from part 1), and  (from part 2)

using Forward Euler. Use the following notation in your discretized

equations:

(from part 2)

using Forward Euler. Use the following notation in your discretized

equations:

where  is the time step,

is the time step,  is the value

of

is the value

of  at

at  ,

,  is the value of

is the value of  at

at

.

.

Part 11

The Kuhn-Tucker loading-unloading conditions are

Write down a discrete form of the Kuhn-Tucker conditions.

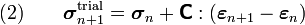

Part 12

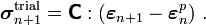

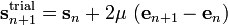

In the radial return algorithm, we define a trial elastic state as

where  are the stress and strain at

are the stress and strain at  and

and

are the values at

are the values at  . Show

that, if the elastic response of the material is linear,

equation (2) can be written as

. Show

that, if the elastic response of the material is linear,

equation (2) can be written as

Hint: Start by showing that

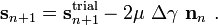

Part 13

Starting from equation (3) show that

where  is the deviatoric part of

is the deviatoric part of  and

and  is the

deviatoric part of

is the

deviatoric part of  .

.

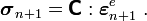

Part 14

Show that

Hint: The stress  is given by

is given by

Express this equation in terms of  and

and  .

Then use the discretized equation for

.

Then use the discretized equation for  (part 10) and

the relation for

(part 10) and

the relation for  for isotropic elasticity. Finally compute

the deviatoric stress terms after showing that

for isotropic elasticity. Finally compute

the deviatoric stress terms after showing that

Part 15

The discretized form of the Kuhn-Tucker conditions in conjunction with the consistency condition gives us

Use this condition and the relations you have derived in the

previous sections to arrive at a nonlinear equation in  that can be solved using Newton iterations.

that can be solved using Newton iterations.

Part 16

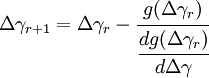

Let the nonlinear equation be  . Recall that

the Newton method requires that we iterate using the formula

. Recall that

the Newton method requires that we iterate using the formula

where  is the Newton iteration number. Derive an expression for

the derivative of

is the Newton iteration number. Derive an expression for

the derivative of  that is required in the above formula.

that is required in the above formula.

(You can use Computational Inelasticity by J.C. Simo and T.J.R. Hughes for pointers.)

Problem 2: Billet Upset Forging

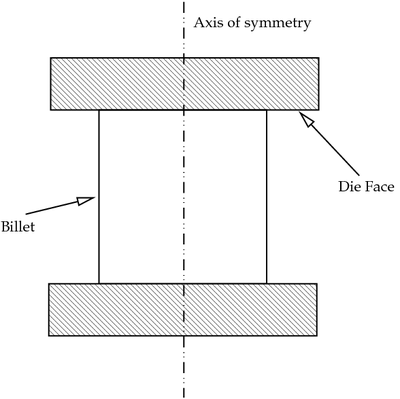

Consider the isothermal upset forging of the cylindrical billet shown in Figure 2.

Figure 2. Upset forging of a cylindrical billet. |

Assume that the dies are rigid. Also assume that sticking friction is in effect between the billet and the die faces when they are in contact.

The billet has an initial radius of 10 mm and its initial height is 30 mm. The shear modulus of the material is 384.6 MPa, the bulk modulus of the material is 833.3 MPa, the initial yield stress is 1 MPa and the linear hardening modulus is 3 MPa.

Model a quarter of the cylinder using symmetry boundary conditions.

Apply a compressive force of 1 kN to the die.

- Plot the final shape of the billet. Compare your results with those shown in Simo and Hughes (Fig. 9.8, p. 325).

- Plot a curve of the die force (kN) versus the die stroke (mm). Compare your results with those shown in Simo and Hughes. Do you observe any volumetric locking?

(Use an implicit software to solve these problems.)

Problem 3: Taylor Impact Tests

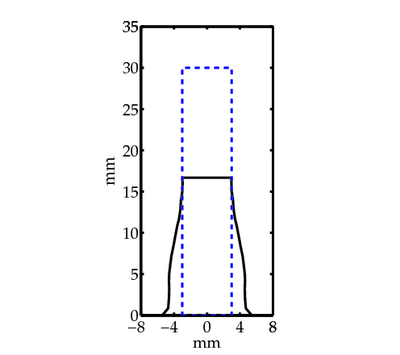

Consider the impact of a cylindrical Taylor impact specimen on a rigid target. The undeformed and deformed profiles of the specimen are shown in in Figure 3.

Figure 3. Taylor impact test of a cylindrical rod. |

The initial length of the specimen is 30 mm. The initial diameter is 6 mm. The initial velocity is 188 m/s. The initial temperature is 718 K.

The material of the specimen is OFHC copper. The properties of the bar are (in SI units):

| Density | 8930.0 |

| Thermal conductivity | 386.0 |

| Specific heat | 414.0 |

| Shear modulus | 46.0e9 |

| Bulk modulus | 129.0e9 |

| Coeff. Thermal Expansion | 1.76e-5 |

The plastic deformation of the specimen is described by the Johnson-Cook

model and  plasticity. The Johnson-Cook model parameters are (in SI

units):

plasticity. The Johnson-Cook model parameters are (in SI

units):

| A | 90.0e6 |

| B | 292.0e6 |

| C | 0.025 |

| n | 0.31 |

| m | 1.09 |

|

1.0 |

|

294.0 |

|

1356.0 |

- Use LS-DYNA to simulate the Taylor impact test. Assume that there is no friction between the anvil and the specimen. Plot the final deformed shape of the specimen and compare that with the experimentally determined shape given in the table below. What differences do you observe and why?

Point x (mm) y (mm) 1 0.000000 0.000000 2 5.436409 0.000000 3 4.711554 0.852540 4 4.611804 2.040725 5 4.581879 3.228910 6 4.615129 4.141866 7 4.585204 4.980980 8 4.448878 6.175878 9 4.312552 7.223092 10 4.073150 8.344149 11 3.870324 9.465205 12 3.597672 10.868203 13 3.388196 11.707317 14 3.218620 12.902215 15 3.152120 13.949429 16 2.982544 15.070486 17 2.952618 16.674871 18 0.000000 16.674871 19 0.000000 0.000000 - You can generate a mesh in ANSYS and tranfer it to LS-DYNA if you want.

- Show whether energy is conserved during your simulation.

![\boldsymbol{\varepsilon} = \frac{1}{2}\left[\boldsymbol{\nabla} \mathbf{u} + (\boldsymbol{\nabla} \mathbf{u})^T\right]

\qquad\text{or}\qquad

\varepsilon_{ij} = \frac{1}{2}(u_{i,j} + u_{j,i}) ~.](../I/m/3e0528ea1083641d57f5c12abdb24b8d.png)

![\sigma_y(\alpha,T) = \left[\sigma_0 + B \alpha^n\right]

\left[1 - \left(\cfrac{T - T_0}{T_m -T_0}\right)\right]](../I/m/f7cbc76d40e8cc0bcd63fbcf1a62bd7c.png)

![\text{(3)} \qquad

\boldsymbol{\sigma}_{n+1}^{\text{trial}} =

\left[\lambda~\text{tr}(\boldsymbol{\varepsilon}_{n+1})~\boldsymbol{\mathit{1}} + 2\mu~\boldsymbol{\varepsilon}_{n+1}\right] -

\left[\lambda~\text{tr}(\boldsymbol{\varepsilon}_n^p)~\boldsymbol{\mathit{1}} + 2\mu~\boldsymbol{\varepsilon}_n^p\right] ~.](../I/m/85513053d9eea5ebaf9ba98227065df7.png)