Introduction to finite elements/Axial bar finite element solution

< Introduction to finite elementsAxially loaded bar: The Finite Element Solution

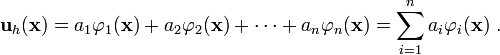

The finite element method is a type of Galerkin method that has the following advantages:

- The functions

are found in a systematic manner.

are found in a systematic manner. - The functions

are chosen such that they can be used for arbitrary domains.

are chosen such that they can be used for arbitrary domains. - The functions

are piecewise polynomials.

are piecewise polynomials. - The functions

are non-zero only on a small part of the domain.

are non-zero only on a small part of the domain.

As a result, computations can be done in a modular manner that is suitable for computer implementation.

Discretization

The first step in the finite element approach is to divide the domain into elements and nodes, i.e., to create the finite element mesh.

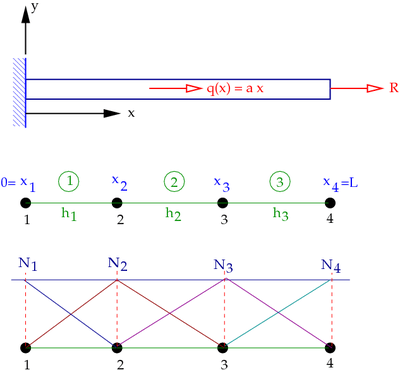

Let us consider a simple situation and divide the rod into 3 elements and 4 nodes as shown in Figure 6.

Figure 6. Finite element mesh and basis functions for the bar. |

Shape functions

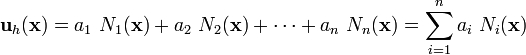

The functions  have special characteristics in finite element methods and are generally written as

have special characteristics in finite element methods and are generally written as  and are called basis functions, shape functions, or interpolation functions.

and are called basis functions, shape functions, or interpolation functions.

Therefore, we may write

The finite element basis functions are chosen such that they have the following properties:

- The functions

are bounded and continuous.

are bounded and continuous. - If there are

nodes, then there are

nodes, then there are  basis functions - one for each node. There are four basis functions for the mesh shown in Figure 6.

basis functions - one for each node. There are four basis functions for the mesh shown in Figure 6. - Each function

is nonzero only on elements connected to node

is nonzero only on elements connected to node  .

.  is 1 at node

is 1 at node  and zero at all other nodes.

and zero at all other nodes.

Stiffness matrix

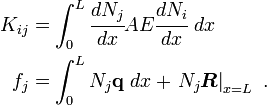

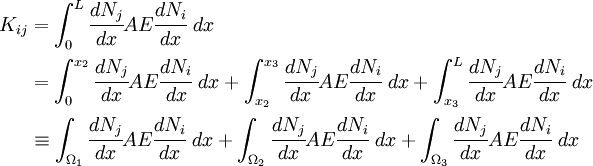

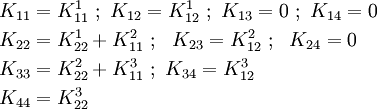

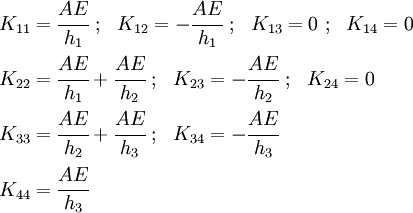

Let us compute the values of  for the three element mesh. We have

for the three element mesh. We have

The components of  are

are

The matrix  is symmetric, so we don't need to explicitly compute the other terms.

is symmetric, so we don't need to explicitly compute the other terms.

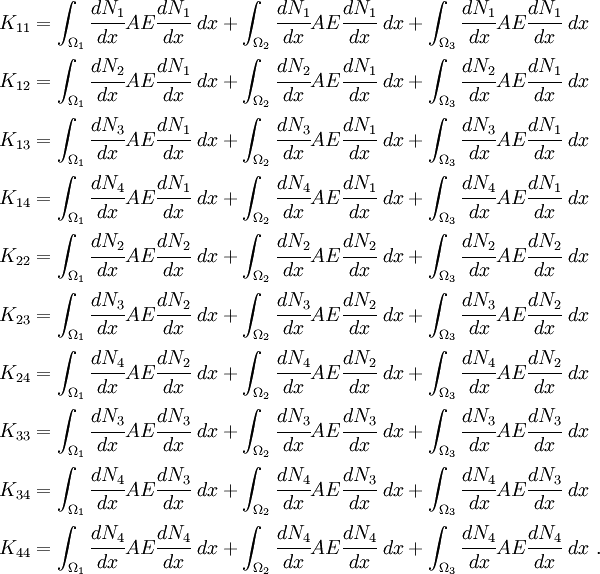

From Figure 6, we see that  is zero in elements 2 and 3,

is zero in elements 2 and 3,  is zero in element 3,

is zero in element 3,  is zero in element 1, and

is zero in element 1, and  is zero in elements 1 and 2. The same holds for

is zero in elements 1 and 2. The same holds for  .

.

Therefore, the coefficients of the  matrix become

matrix become

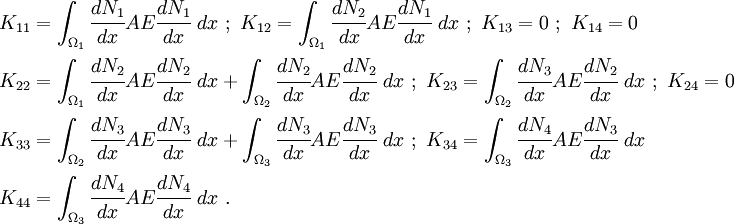

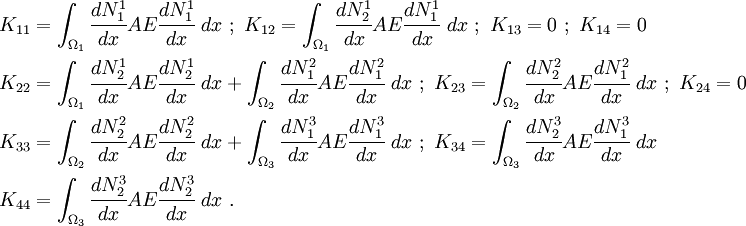

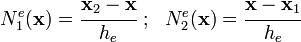

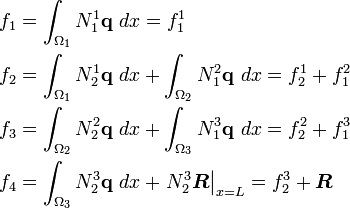

We can simplify our calculation further by letting  be the shape functions over an element

be the shape functions over an element  . For example, the shape functions over element

. For example, the shape functions over element  are

are  and

and  where the local nodes

where the local nodes  and

and  correspond to global nodes

correspond to global nodes  and

and  , respectively. Then we can write,

, respectively. Then we can write,

Let  be the part of the value of

be the part of the value of  that is contributed by element

that is contributed by element  . The indices

. The indices  are local and the indices

are local and the indices  are global. Then,

are global. Then,

We can therefore see that if we compute the stiffness matrices over

each element and assemble them in an appropriate manner, we can get the

global stiffness matrix  .

.

Stiffness matrix for two-noded elements

For our problem, if we consider an element  with two nodes, the local hat shape functions have the form

with two nodes, the local hat shape functions have the form

where  is the length of the element.

is the length of the element.

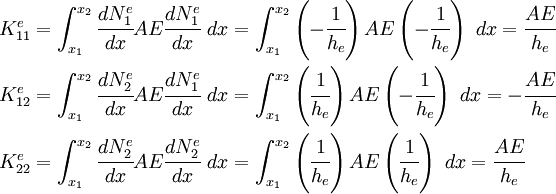

Then, the components of the element stiffness matrix are

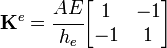

In matrix form,

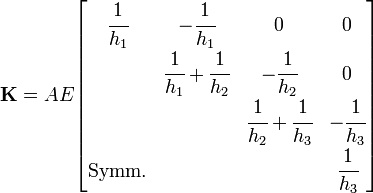

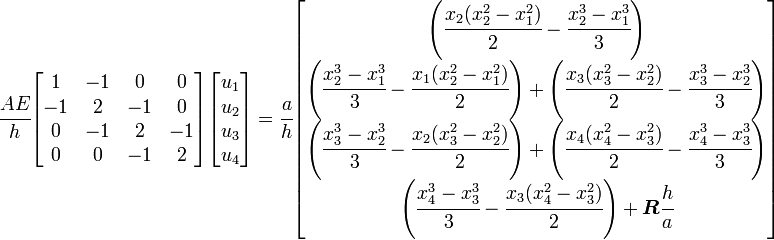

The components of the global stiffness matrix are

In matrix form,

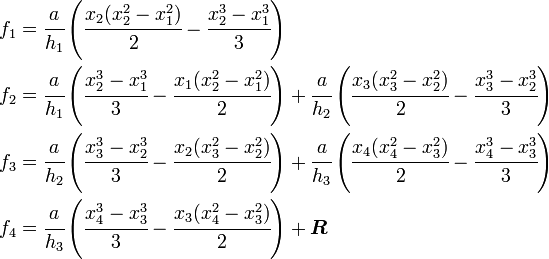

Load vector

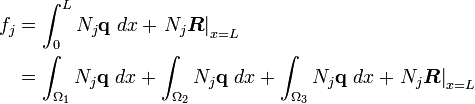

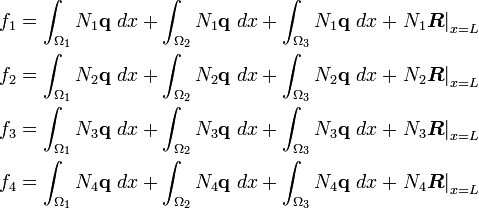

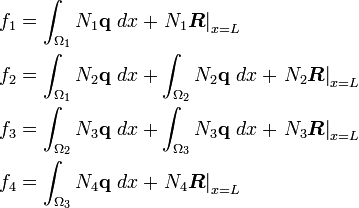

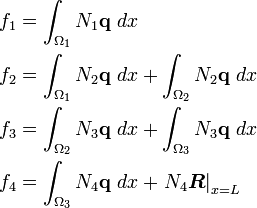

Similarly, for the load vector  , we have

, we have

The components of the load vector are

Once again, since  is zero in elements 2 and 3,

is zero in elements 2 and 3,  is zero in element 3,

is zero in element 3,  is zero in element 1, and

is zero in element 1, and  is zero in elements 1 and 2, we have

is zero in elements 1 and 2, we have

Now, the boundary  is at node 4 which is attached to element 3. The only non-zero shape function at this node is

is at node 4 which is attached to element 3. The only non-zero shape function at this node is  . Therefore, we have

. Therefore, we have

In terms of element shape functions, the above equations can be written as

The above shows that the global load vector can also be assembled from the element load vectors if we use finite element shape functions.

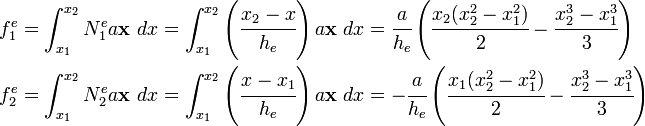

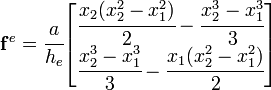

Load vector for two-noded elements

Using the linear shape functions discussed earlier and replacing  with

with  , the components of the element load vector

, the components of the element load vector  are

are

In matrix form, the element load vector is written

Therefore, the components of the global load vector are

Displacement trial function

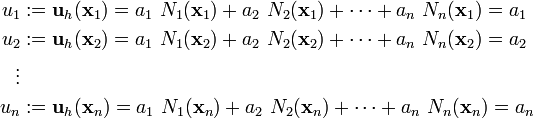

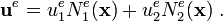

Recall that we assumed that the displacement can be written as

If we use finite element shape functions, we can write the above as

where  is the total number of nodes in the domain. Also, recall that the value of

is the total number of nodes in the domain. Also, recall that the value of  is 1 at node

is 1 at node  and zero elsewhere. Therefore, we have

and zero elsewhere. Therefore, we have

Therefore, the trial function can be written as

where  are the nodal displacements.

are the nodal displacements.

Finite element system of equations

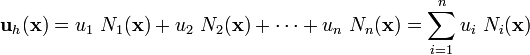

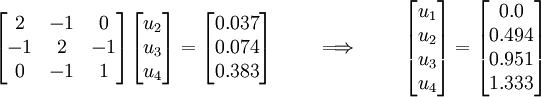

If all the elements are assumed to be of the same length  , the finite element system of equations (

, the finite element system of equations ( ) can then be written as

) can then be written as

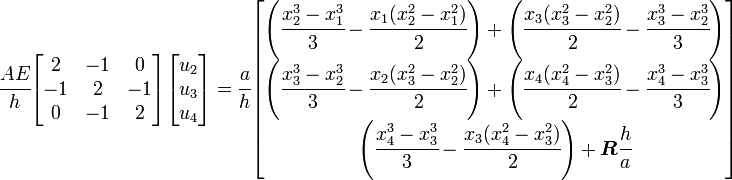

Essential boundary conditions

To solve this system of equations we have to apply the essential boundary condition  at

at  . This is equivalent to setting

. This is equivalent to setting  . The reduced system of equations is

. The reduced system of equations is

This system of equations can be solved for  ,

,  , and

, and  . Let us do that.

. Let us do that.

Assume that  ,

,  ,

,  ,

,  , and

, and  are all equal to 1. Then

are all equal to 1. Then  ,

,  ,

,  ,

,  , and

, and  . The system of equations becomes

. The system of equations becomes

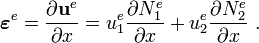

Computing element strains and stresses

From the above, it is clear that the displacement field within an element  is given by

is given by

Therefore, the strain within an element is

In matrix notation,

The stress in the element is given by

For our discretization, the element stresses are

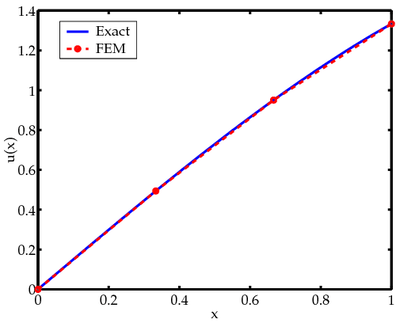

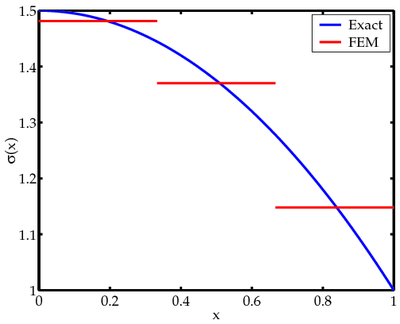

A plot of this solution is shown in Figure 7.

Figure 7(a). FEM vs exact solutions for displacements of an axially loaded bar. |

Figure 7(b). FEM vs exact solutions for stresses in an axially loaded bar. |

Matlab code

The finite element code (Matlab) used to compute this solution is given below.

function AxialBarFEM

A = 1.0;

L = 1.0;

E = 1.0;

a = 1.0;

R = 1.0;

e = 3;

h = L/e;

n = e+1;

for i=1:n

node(i) = (i-1)*h;

end

for i=1:e

elem(i,:) = [i i+1];

end

K = zeros(n);

f = zeros(n,1);

for i=1:e

node1 = elem(i,1);

node2 = elem(i,2);

Ke = elementStiffness(A, E, h);

fe = elementLoad(node(node1),node(node2), a, h);

K(node1:node2,node1:node2) = K(node1:node2,node1:node2) + Ke;

f(node1:node2) = f(node1:node2) + fe;

end

f(n) = f(n) + 1.0;

Kred = K(2:n,2:n);

fred = f(2:n);

d = inv(Kred)*fred;

dsol = [0 d'];

fsol = K*dsol';

sum(fsol)

figure;

p0 = plotDisp(E, A, L, R, a);

p1 = plot(node, dsol, 'ro--', 'LineWidth', 3); hold on;

legend([p0 p1],'Exact','FEM');

for i=1:e

node1 = elem(i,1);

node2 = elem(i,2);

u1 = dsol(node1);

u2 = dsol(node2);

[eps(i), sig(i)] = elementStrainStress(u1, u2, E, h);

end

figure;

p0 = plotStress(E, A, L, R, a);

for i=1:e

node1 = node(elem(i,1));

node2 = node(elem(i,2));

p1 = plot([node1 node2], [sig(i) sig(i)], 'r-','LineWidth',3); hold on;

end

legend([p0 p1],'Exact','FEM');

function [p] = plotDisp(E, A, L, R, a)

dx = 0.01;

nseg = L/dx;

for i=1:nseg+1

x(i) = (i-1)*dx;

u(i) = (1/6*A*E)*(-a*x(i)^3 + (6*R + 3*a*L^2)*x(i));

end

p = plot(x, u, 'LineWidth', 3); hold on;

xlabel('x', 'FontName', 'palatino', 'FontSize', 18);

ylabel('u(x)', 'FontName', 'palatino', 'FontSize', 18);

set(gca, 'LineWidth', 3, 'FontName', 'palatino', 'FontSize', 18);

function [p] = plotStress(E, A, L, R, a)

dx = 0.01;

nseg = L/dx;

for i=1:nseg+1

x(i) = (i-1)*dx;

sig(i) = (1/2*A*E)*(-a*x(i)^2 + (2*R + a*L^2));

end

p = plot(x, sig, 'LineWidth', 3); hold on;

xlabel('x', 'FontName', 'palatino', 'FontSize', 18);

ylabel('\sigma(x)', 'FontName', 'palatino', 'FontSize', 18);

set(gca, 'LineWidth', 3, 'FontName', 'palatino', 'FontSize', 18);

function [Ke] = elementStiffness(A, E, h)

Ke = (A*E/h)*[[1 -1];[-1 1]];

function [fe] = elementLoad(node1, node2, a, h)

x1 = node1;

x2 = node2;

fe1 = a*x2/(2*h)*(x2^2-x1^2) - a/(3*h)*(x2^3-x1^3);

fe2 = -a*x1/(2*h)*(x2^2-x1^2) + a/(3*h)*(x2^3-x1^3);

fe = [fe1;fe2];

function [eps, sig] = elementStrainStress(u1, u2, E, h)

B = [-1/h 1/h];

u = [u1; u2];

eps = B*u

sig = E*eps;

![\boldsymbol{\varepsilon}^e = \mathbf{B}^e \mathbf{u}^e

= \left[ \frac{\partial N^e_1}{\partial x} ~~ \frac{\partial N^e_2}{\partial x}\right]

\begin{bmatrix} u^e_1 \\ u^e_2 \end{bmatrix}

= \left[ -\cfrac{1}{h} ~~ \cfrac{1}{h} \right]

\begin{bmatrix} u^e_1 \\ u^e_2 \end{bmatrix}](../I/m/56b1f6cb64454c55ac81633f0a3fd445.png)