Practical Electronics/perfboard

< Practical Electronics

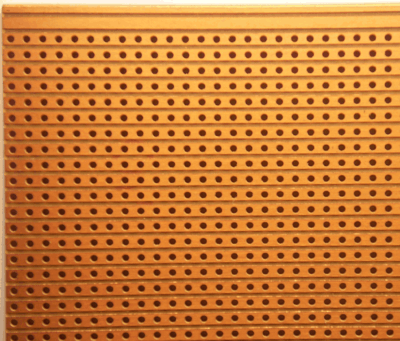

close up of unused Veroboard

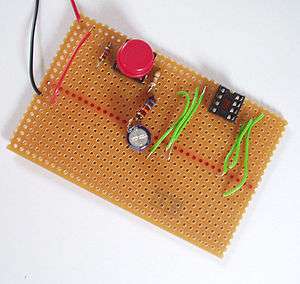

simple circuit using stripboard (component side)

There are many types of "perforated prototyping board".

The vast majority of such boards are perforated at 10 holes per inch both horizontally and vertically (also called "tenth inch spacing"), made out of either "synthetic resin bonded paper" or fiberglass, and have some kind of copper pattern on one or both sides of the board.

Perhaps the most popular pattern is "stripboard" -- which has wide strips of copper running one way all the way along one side of the board, but no copper on the other side.

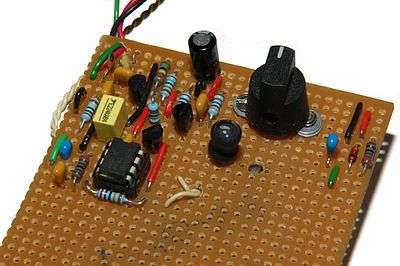

buzzer made using stripboard

Because the strips (copper traces on the solder side) run left-and-right, the components (on the component size) usually run up-and-down.

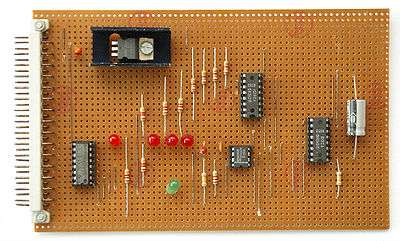

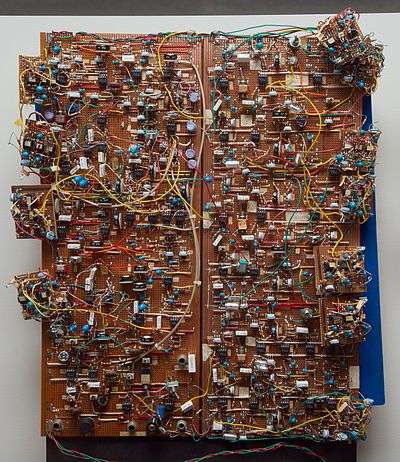

component side of AM receiver

solder side of same AM receiver. DIP integrated circuits usually require traces to be cut between their 2 rows of pins

Complex circuits, such as Dolby SR, have been built on stripboard.

close up of unused "3-Hole Solder Pad" prototyping board, also called "TriPad"

further reading

- Open Circuits: stripboard

- Commons Wikimedia: gallery of stripboard images

- Wikipedia: stripboard

- Wikipedia: perfboard

- Wikipedia: Veroboard

This article is issued from Wikibooks. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.